Mold Manufacturing

Build Perfect Molds for Better Production Parts

Our tooling center is able to offer various types of injection mold tooling, but mainly specializing in the design and manufacturing for automotive and home appliance fields.

We can provide customer with a single-source service, starting from DFM, Mold flow analysis to tooling build.

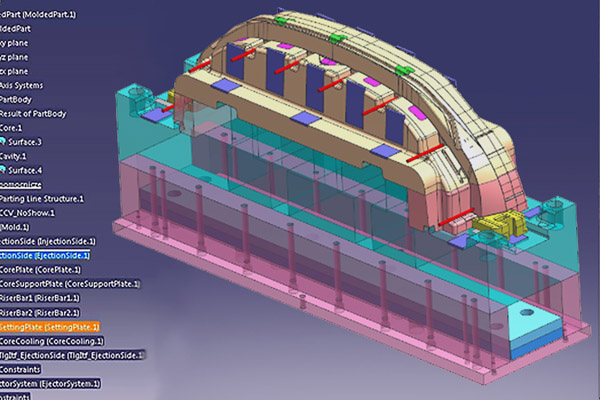

Mold Design

Being a manufacturer in the plastic injection mold industry, we understand that a quality component begins with a good mold and a good part design. A thorough mold design is essential for producing a high-perfomrance mold.

Mold Manufacturing Center

We emphasize on customer satisfaction and product quality, so our key succes factor of mold making is the quality. We focus on both advanced technology and professional people for our team to quarantee that our product exceed our customer expectations.

Type of Molds

Whether you need a new mold designed and machined from aluminum, stainless steel, or tool steel, or repairs for an existing mold, CheeYuen can provide you with the expertise and craftsmanship to deliver quality molds and mold services. For more information on our custom injection mold tool making services, see the table below or contact us directly.

Automotive Components

Home Appliance & Bathroom

2K Injection Molding

With over 33 years of experience in the mold manufacturing

We have a complete production process

We produce and provide OEM and REM customers

Product quality complies with international standards

Molding Equipment List

| No. | MACHINE | MODEL | QTY (SETS) | MANUFACTURER |

| 1 | CNC Machining Center | GF12 | 12 | JANPEN MAKINO |

| 2 | Electric Discharge Machine | 35P | 15 | CHARMILLES |

| 3 | LS-WEDM | 390 | 12 | CHARMILLES |

| 4 | Medium Speed Cutting Machine | DK7750 | 8 | SANGUAN |

| 5 | Milling Machine | 4S | 18 | JIECHONGDA |

| 6 | Grinding Machine | HF-618S | 13 | WANGPAN |

| 7 | Drilling Machine | TRE-1700D | 6 | JANPEN |

| 8 | FIT Tooling Machine | LS-120-1310 | 1 | HONGKONG |

| 9 | Roll Over Machine | MF-5 | 1 | HONGKONG |

| 10 | Lathe | C6240A | 1 | NANFANG |

| 11 | CMM | IMS IMPACT II | 1 | ENGLAND |

Injection Mold Tool Making Capabilities

General Production Capabilities

In-House Full Service Capability

Existing Tooling Transfers

Off-Shore Mold Building Alliances

Mold Management/Mold Maintenance

Mold Repair

Mold and product Design

Engineering Support

Tool History Documentation

Molding problem Solutions

Moldflow Analysis

Tooling or Mold Offered

Soft Tooling

Hard Tooling

Tolerance limit Control (+/-)

Grade A2

±. .0005 in. Within Cavity Shape

Grade A1

±. .005 mm. Within Cavity Shape

Precision Machining

Custom Torelance

Mchining Capabilities

CNC 3D Machining

Electrical Discharge Machining(EDM)

Polishing

Texturing

Design Capabilities

CAD Modeling (2-D, 3-D)

3D Mold Design

Moldflow Analysis

Design for Manufacturable