Custom Plastic Chrome Plating Services: Tailored Solutions for Your Needs

Plastic chrome plating is a process where a metallic finish is applied to plastic components, combining the lightweight benefits of plastic with the premium appearance and durability of metal. This innovative technique delivers exceptional results for a variety of industries, blending functionality with aesthetic appeal.

Key Benefits of Chrome Plating on Plastic:

Enhanced Aesthetic Appeal: Provides a sleek, metallic finish for a high-end look.

Improved Durability: Protects against corrosion, UV damage, and wear.

Lightweight Advantage: Ideal for automotive and decorative applications.

CheeYuen is a renowned injection molding and electroplating company with a 54-year legacy, recognized for its outstanding products and industry expertise. With a steadfast commitment to quality and innovation, CheeYuen continues to set benchmarks in the field of plastic chrome plating.

Plastic Plating Line Capability

A reliable plastic chrome plating company should be equipped with advanced plating lines capable of handling a wide range of parts. Custom plating often comes with higher client demands, which test the technical expertise and production capacity of the plating provider. Essential equipment includes:

Automatic plating line:

A plating tank size of at least 300120150 cm, suitable for large parts like grilles, trims, and automotive or home appliance components.

Circular plating line:

A tank size of around 7590150 cm, ideal for medium to small parts such as logos, knobs, and levers.

To meet high-volume production demands, the company should have a plating capacity of at least 1.5 million square meters per year, ensuring efficiency and consistent quality.

Additionally, the company must be equipped with top-tier control systems like the AUCOS control system, MeFiag filters, and CRS rectifiers to ensure precision and uniformity throughout the plating process. These advanced technologies are essential to meet the high standards required for custom plating, where the demands for quality, design, and finish can be particularly challenging.

The use of high-quality electroplating chemicals from reputable suppliers such as MacDermid-Enthone, Atotech, and JCU ensures excellent results across various industries, including automotive, home appliances, and bathroom parts. Custom requests often involve unique requirements, and a plating company with the right technology and expertise is vital to meeting these needs while maintaining superior quality and consistency.

Tailored Plastic Plating Service

Custom plastic plating services require a deep understanding of the customer’s needs, especially when it comes to replicating sample dimensions, functionality, and color. Achieving precise color matching and high-quality finishes is essential, particularly for automotive, home appliance, and decorative parts.

To ensure a successful outcome, plating providers must balance customization with high production yields and consistent quality. By leveraging advanced technology and skilled expertise, a reliable plating service can deliver exact results that meet the customer’s specifications, ensuring a win-win for both the client and the manufacturer.

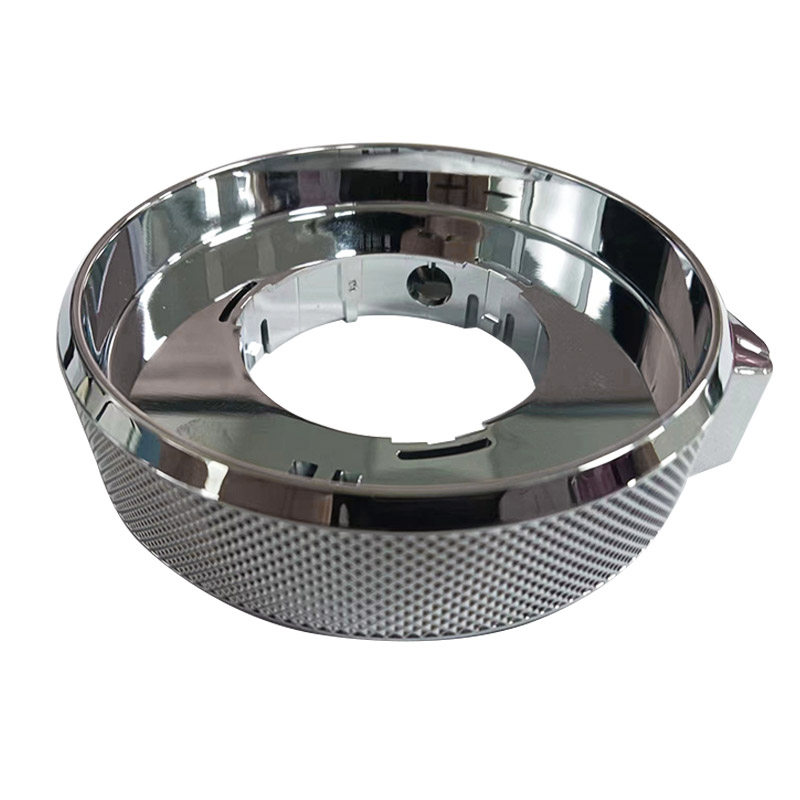

Knurled Ring: Diamond texture

Car Door Handle

Cooktop-Burner-Control-Knob

Bright Chromed Faucet

Trivalent Brigt Chrome Ring

Learn More About Our Plastic Chrome Plating Services

Write your message here and send it to us

Rigorous Quality Control

Inspection is a vital component of Cheeyuen’s comprehensive quality control system. As a crucial step in ensuring product excellence, it involves a detailed evaluation of chrome-plated parts to identify any defects or inconsistencies. From surface finish to color uniformity and structural integrity, every aspect is meticulously checked to meet industry standards and client specifications by integrating inspection into a broader quality control framework.

To meet your custom chrome plating needs, partner with a facility that excels in:

Environmental Compliance: Adheres to global standards like RoHS and REACH certifications for safe, compliant plating processes.

Reliable Production: Streamlined processes ensure consistent quality and on-time delivery, even for high-volume projects.

Various Performance Test: Adhesion test, CASS test, Thermal Shock test, Saw Grind test, Flammability test.

Choosing the right plating factory ensures precision, compliance, and dependable results for your custom projects.

Common Challenges in Plastic Chrome Plating

Achieving consistency in the chrome plating on plastic process requires overcoming challenges such as:

Surface preparation:

Ensuring the base material is clean and defect-free to avoid imperfections during the plastic plating treatment solutions phase.

Adhesion issues:

Using advanced pre-treatments and adhesion promoters to secure a strong bond during the chromium plating process.

Environmental factors:

Managing variables like temperature, humidity, and chemical concentrations to produce a flawless chrome finish on plastic every time.

Future Trends in Chrome Plating

As industries move toward sustainability and innovation, plastic chrome plating companies are embracing new technologies such as:

Eco-friendly chrome solutions:

Adoption of water-based coatings to reduce environmental impact while maintaining premium quality.

Advanced chrome finishes:

Development of fingerprint-resistant coatings and ultra-matte finishes, enhancing functionality and aesthetics.

Electric vehicle applications:

Focus on lightweight and aesthetic chrome-plated EV parts, perfectly aligning with emerging automotive trends.

People Also Ask:

What is custom plastic chrome plating?

Custom plastic chrome plating is a process where a thin layer of chromium is electroplated onto a plastic substrate. This enhances the plastic’s appearance with a shiny, durable chrome finish and provides added benefits like corrosion resistance, wear resistance, and aesthetic appeal. The process is customized to suit specific client needs, offering flexibility for different shapes, sizes, and applications.

What types of products can be chrome-plated?

We offer chrome plating services for a wide range of products, including automotive parts, home appliance components, bathroom fixtures, decorative trims, knobs, buttons, grilles, emblems, and more. Whether you’re working with small or large parts, our facilities are equipped to handle various shapes and sizes.

What are the key advantages of custom plastic chrome plating?How do you ensure consistent quality in your plating process?

Aesthetic Appeal: The shiny, mirror-like finish elevates the look of products.

Durability: Chrome plating adds a layer of protection against corrosion, scratches, and wear.

Custom Fit: Tailored solutions ensure that the finish matches your exact specifications for form and function.

Corrosion Resistance: Chrome plating helps protect parts from oxidation and rust, extending their lifespan. Our production lines are equipped with advanced technology, including the AUCOS control system and high-performance MeFiag filters. We also use CRS rectifiers for precise current control during plating. Each product undergoes rigorous quality control checks to ensure uniformity and consistency, regardless of the size or complexity of the part.

What is your production capacity for custom chrome plating?

We are capable of plating 1.5 million square meters per year, which enables us to handle high-volume production needs while maintaining high-quality standards.

What are the size limitations for parts that can be chrome-plated?

We can accommodate both large and small parts. Our automatic plating line can handle parts up to 300120150 cm, ideal for larger automotive or home appliance components. The circular plating line can handle parts up to 7590150 cm, perfect for medium-sized items like logos and knobs.

Can I order small batches or prototypes?

Yes, we provide flexibility for both small-batch orders and large-volume production. Whether you’re testing a new product or require a limited number of items, we can tailor our services to meet your needs.

What electroplating chemicals do you use?

We use high-quality electroplating chemicals from trusted suppliers like MacDermid-Enthone, Atotech, and JCU. These chemicals ensure consistent results with exceptional durability and finish quality.

How long does the chrome plating process take?

The plating process timeline varies depending on factors such as part size, complexity, and order volume. For standard parts, the process typically takes a few days, but we will provide an estimated timeline upon reviewing your specific requirements.

Are your plating services environmentally friendly?

Yes, we adhere to strict environmental standards, including RoHS compliance and REACH certification. Our processes are designed to minimize waste and reduce environmental impact, ensuring sustainable practices in every project we undertake.

What industries do you serve?

Our custom plastic chrome plating services cater to industries such as automotive, home appliances, bathroom fixtures, and consumer electronics. No matter your sector, we provide high-quality finishes tailored to your specific needs.

How can I request a quote for my project?

To get a customized quote, simply reach out to us with details about your project, including the type of parts, quantity, and any specific requirements for plating. We will provide a competitive quote based on your specifications.